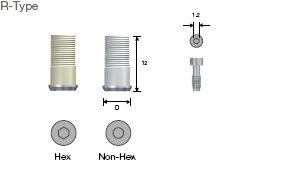

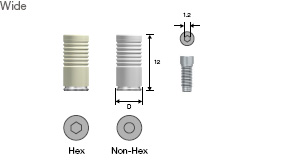

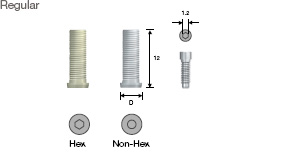

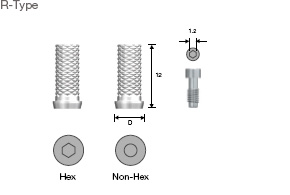

- ㆍUse for cases with path and aesthetic and spatial constraints

- ㆍAfter customization, be sure to use only dental gold alloy for casting to make the prosthesis

- ㆍMelting point range of abutment (Au, Pt, Pd alloy) : 1400-1450° (use of non-precious metal alloy for casting prohibited)

- ㆍUsed for the path adjustment of anterior in case of 17° axial angle

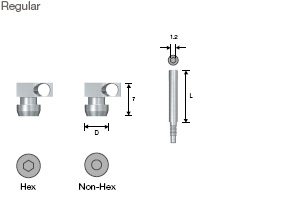

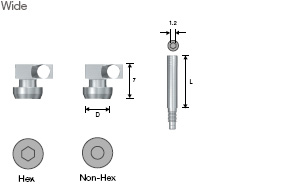

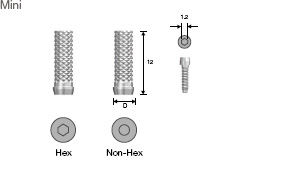

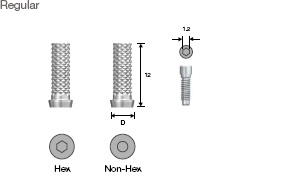

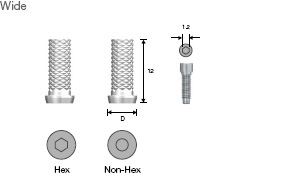

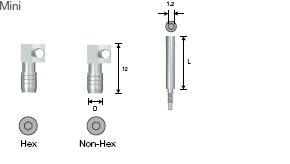

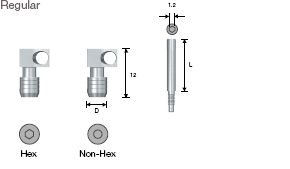

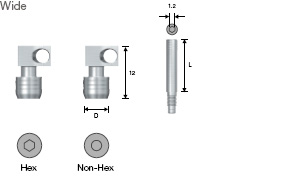

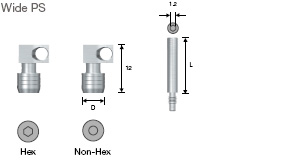

- ㆍUse a 1.2 hex driver

- ㆍPacking unit : Abutment + Ti screw

- ㆍTightening torque : Ti screw : 30Ncm

Order code - Abutment + Ti Screw : Product Code + TH (ex :GCR200TH)

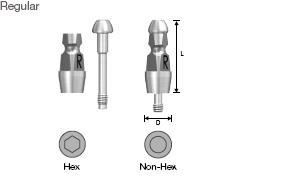

| |

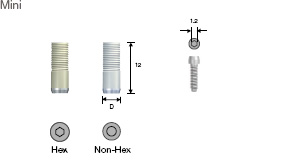

ø 3.5 |

| Hex |

GCM200 |

| Non-Hex |

GCM100 |

| Screw |

Ti |

USABSMT |

| |

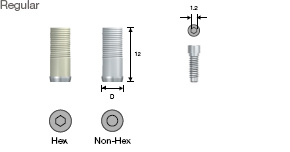

ø 4.5 |

| Hex |

GCR200 |

| Non-Hex |

GCR100 |

| Screw |

Ti |

ASR200° |

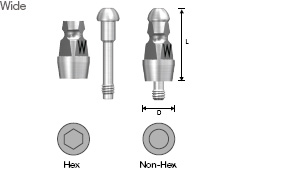

| |

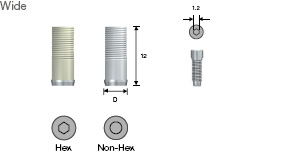

ø 5.5 |

| Hex |

GCR200 |

| Non-Hex |

GCR100 |

| Screw |

Ti |

ASR200° |

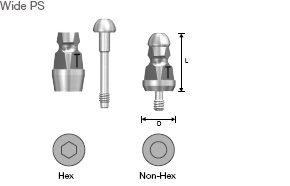

| |

ø 5.5 |

| Hex |

TGCW200 |

| Non-Hex |

TGCW100 |

| Screw |

Ti |

ASR200° |

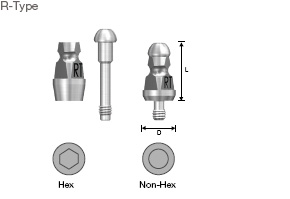

| |

ø 5.5 |

| Hex |

RGCW200 |

| Non-Hex |

RGCW100 |

| Screw |

Ti |

RASW200° |

- ㆍPacking unit : Abutment + Ti screw

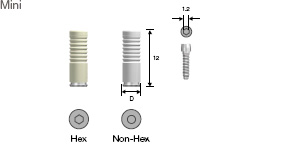

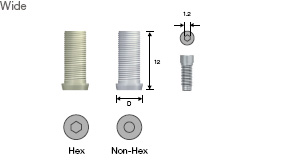

- ㆍUse for cases with path and aesthetic and spatial constraints

- ㆍAfter customization, be sure to use only dental non-precious metal alloy for casting to make the

Prosthesis

- ㆍLower precision in the joints compared to UCLA Gold Abutments

- ㆍUse a 1.2 hex driver

- ㆍTightening torque : Ti screw : 30Ncm

Order code - Abutment + Ti Screw : Product Code + TH (ex :NCR200STH)

| |

ø 4.0 |

| Hex |

NCM200 |

| Non-Hex |

NCM100 |

| Ti Screw |

USABSMT |

| |

ø 4.5 |

| Hex |

NCR200 |

| Non-Hex |

NCR100 |

| Ti Screw |

ASR200 |

| |

ø 5.5 |

| Hex |

NCW200 |

| Non-Hex |

NCW100 |

| Ti Screw |

ASW200 |

| |

ø 5.5 |

| Hex |

TNCW200 |

| Non-Hex |

TNCW100 |

| Ti Screw |

ASR200 |

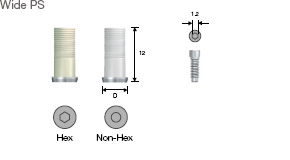

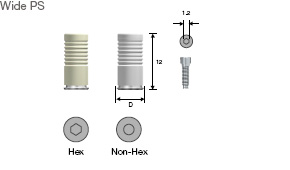

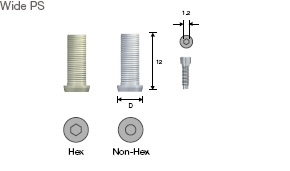

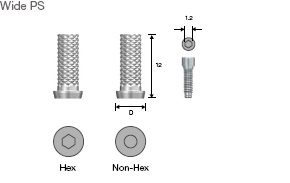

- ㆍUse for cases with path and aesthetic and spatial constraints

- ㆍAfter customization, dental alloy (gold, non-precious metal) is used for casting

- ㆍLower precision in the joints compared to UCLA Gold Abutments

- ㆍUse a 1.2 hex driver

- ㆍPacking unit : Abutment + Ti screw

- ㆍTightening torque : 30Ncm

Order code - Abutment + Ti Screw : Product Code + TH (ex :PSR200TH)

| |

ø 4.0 |

| Hex |

PSM200 |

| Non-Hex |

PSM100 |

| Ti Screw |

USABSMT |

| |

ø 4.5 |

| Hex |

PSR200 |

| Non-Hex |

PSR100 |

| Ti Screw |

ASR200 |

| |

ø 5.5 |

| Hex |

PSW200 |

| Non-Hex |

PSW100 |

| Ti Screw |

ASW200 |

| |

ø 5.5 |

| Hex |

TPSW200 |

| Non-Hex |

TPSW100 |

| Ti Screw |

ASR200 |

| |

ø 5.5 |

| Hex |

RPSW200 |

| Non-Hex |

RPSW100 |

| Ti Screw |

RASW200 |

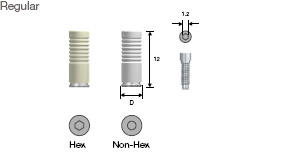

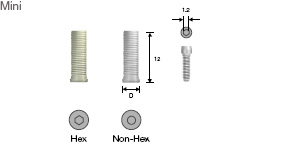

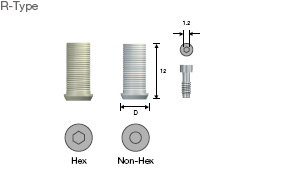

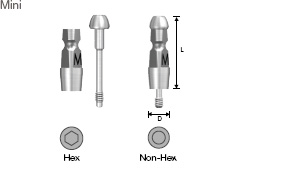

- ㆍUse to make temporary prothesis (material : Ti Gr-3)

- ㆍEasy to customize, designed to minimize indication constraints

- ㆍUse a 1.2 hex driver

- ㆍPacking unit : Abutment + Ti screw

- ㆍTightening torque : 15Ncm

Order code - Abutment + Ti Screw : Product Code + TH (ex :TAR200TH)

| |

ø 4.5 |

| Hex |

TAM200 |

| Non-Hex |

TAM100 |

| Ti Screw |

USABSMT |

| |

ø 4.5 |

| Hex |

TAM200 |

| Non-Hex |

TAM100 |

| Ti Screw |

ASR200 |

| |

ø 5.5 |

| Hex |

TAW200 |

| Non-Hex |

TAW100 |

| Ti Screw |

ASW200 |

| |

ø 5.5 |

| Hex |

TTAW200 |

| Non-Hex |

TTAW100 |

| Ti Screw |

ASR200 |

| |

ø 5.5 |

| Hex |

RTAW200 |

| Non-Hex |

RTAW100 |

| Ti Screw |

RASW200 |

- ㆍTransfer type for taking an impression using a ready-made tray

- ㆍTriangular arc (

) design improves markability following impression

) design improves markability following impression

- ㆍLong and short types enhance convenience

- ㆍThe hex type is designed as a two-piece, and the non-hex type, as a one-piece

- ㆍPacking unit : Impression Coping body + Guide Pin (Hex) / Impression Coping (Non-Hex)

| |

ø4.0 |

| L |

13.5 |

Hex |

ICPM402L |

| Non-Hex |

ICPM401L |

| 10.5 |

Hex |

ICPM402S |

| Non-Hex |

ICPM401S |

| |

ø5.0 |

| L |

13.5 |

Hex |

ICPR502L |

| Non-Hex |

ICPR501L |

| 10.5 |

Hex |

ICPR502S |

| Non-Hex |

ICPR501S |

| |

ø5.0 |

| L |

13.5 |

Hex |

ICPW602L |

| Non-Hex |

ICPW601L |

| 10.5 |

Hex |

ICPW602S |

| Non-Hex |

ICPW601S |

| |

ø6.0 |

| L |

13.5 |

Hex |

TICPW602 |

| 10.5 |

Non-Hex |

TICPW601 |

| |

ø6.0 |

| L |

13.5 |

Hex |

RICPW602 |

| 10.5 |

Non-Hex |

RICPW601 |

- ㆍPick-up type for taking an impression using a customized tray

- ㆍImpression coping designed with Hole-in-one ; no need for resin fixation

- ㆍAsymmetrical structure minimizing contact interference (

)

)

- ㆍLong and short types enhance convenience

- ㆍPacking unit : Impression Coping body + Guide Pin

| |

ø4.0 |

| Hex |

ICFM400 |

| Non-Hex |

ICFM400N |

Guide

Pin (L) |

10 |

- |

| 15 |

CSM150 |

| 17 |

- |

| |

ø5.0 |

ø6.0 |

| Hex |

ICFR500 |

ICFR600 |

| Non-Hex |

ICFR500N |

ICFR600N |

Guide

Pin (L) |

10 |

CSR100 |

| 15 |

CSR150° |

| 17 |

CSR170 |

| |

ø5.0 |

| Hex |

ICFW600 |

| Non-Hex |

ICFW600N |

Guide

Pin (L) |

10 |

CSW100 |

| 15 |

CSW150° |

| 17 |

- |

| |

ø6.0 |

| Hex |

TICFW600 |

| Non-Hex |

TICFW600N |

Guide

Pin (L) |

10 |

- |

| 15 |

TCSW150 |

| 17 |

- |

| |

ø6.0 |

| Hex |

RICFW600 |

| Non-Hex |

RICFW600N |

Guide

Pin (L) |

10 |

- |

| 15 |

RCSW150 |

| 17 |

- |

- ㆍPick-up type for taking an impression using a customized tray

- ㆍImpression coping designed with Hole-in-one ; no need for resin fixation

- ㆍAsymmetrical structure minimizing contact interference (

)

)

- ㆍLong and short types enhance convenience

- ㆍPacking unit : Impression Coping body + Guide Pin

| |

ø5.0 |

| Hex |

ICSR500 |

| Non-Hex |

ICSR500N |

Guide

Pin (L) |

10 |

CSR100° |

| 15 |

CSR150 |

| 17 |

CSR170 |

| |

ø6.0 |

| Hex |

ICSW600 |

| Non-Hex |

ICSW600N |

Guide

Pin (L) |

10 |

CSW100° |

| 15 |

CSW150 |

| 17 |

- |

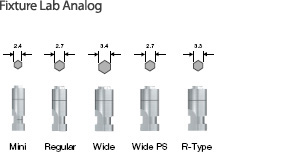

| Mini |

FAM300 |

| Regular |

FAR300 |

| Wide |

FAW300 |

| Wide PS |

TFAW300 |

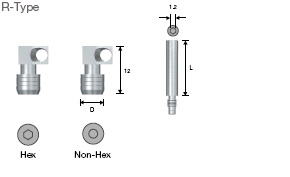

| R-Type |

RFAW300 |

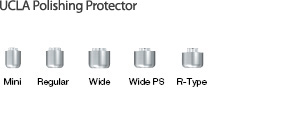

| Mini |

UPCM100 |

| Regular |

UPCR100 |

| Wide |

UPCW100 |

| Wide PS |

TUPCW100 |

| R-Type |

RUPCW100 |

- ㆍFor polishing upon prosthetic casting, use to avoid damaging the cylinder joint

- ㆍPacking unit : Polishing protector

) design improves markability following impression

) design improves markability following impression

)

)

)

)